Unlocking Precision and Efficiency with Summit CNC's 5-Axis Turning Capabilities

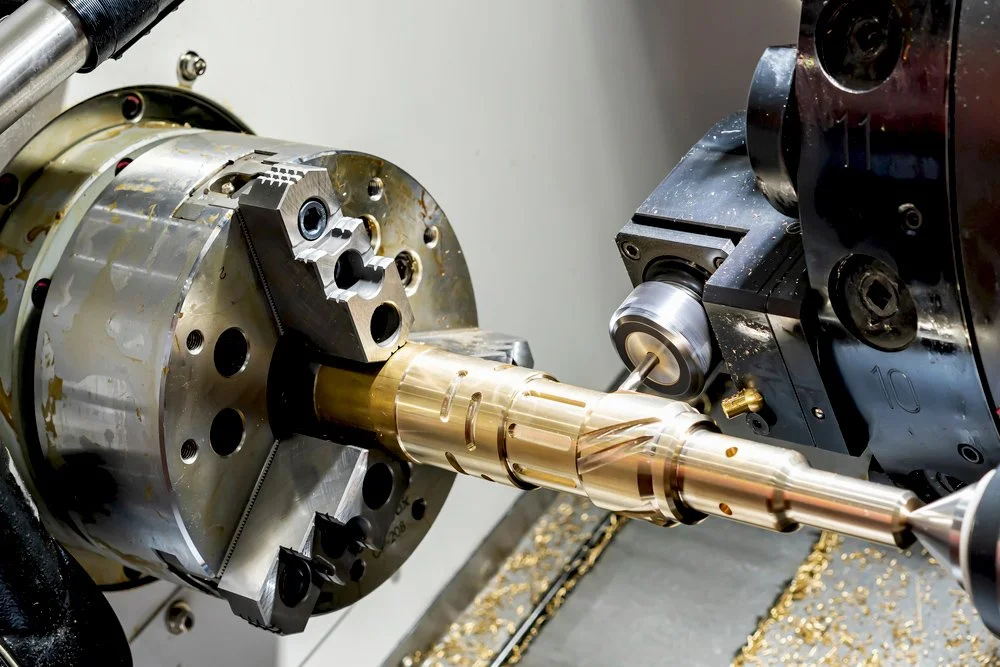

At Summit CNC, based in Denver, Colorado, we are proud to offer 5-axis CNC turning services that push the boundaries of precision and efficiency. Specializing in the machining of complex cylindrical CNC parts, our state-of-the-art turning capabilities set us apart in the industry.

The Power of Live Tooling and a Y-Axis

One of the key features that distinguishes our CNC turning services is our advanced lathe, equipped with live tooling and a Y-axis. This powerful combination enables us to machine almost any kind of asymmetrical feature directly on the lathe. Traditionally, parts with asymmetrical features would need to be transferred to a CNC mill for additional machining, adding time and cost to the process. However, with our integrated solution, we can complete these complex operations in one setup, significantly reducing lead times and overall production costs for our customers.

Precision Turning for Tight Tolerances

When it comes to precision, Summit CNC delivers unparalleled accuracy. Our CNC turning capabilities allow us to achieve tight tolerances down to +/- 0.0001 inches (0.00254 mm). This level of precision can be crucial for industries that demand exacting standards, such as medical devices, aerospace, and defense. Whether you need a single prototype or high-volume production, our team ensures that every part meets the stringent quality requirements that your project demands.

Versatility in Material Machining

At Summit CNC, we understand that each project comes with its own unique material requirements. That’s why our CNC turning services are designed to accommodate a wide range of materials, including both hard and soft metals, as well as various types of plastics. From challenging materials like titanium and Inconel to more common metals and engineering plastics, we have the expertise and equipment necessary to deliver high-quality turned parts every time.

Why Choose Summit CNC for Your CNC Turning Needs?

Reduced Costs and Lead Times: Our live tooling and Y-axis capabilities eliminate the need for multiple setups, reducing both production costs and lead times.

High Precision: We deliver parts with precision tolerances down to +/- 0.0001 inches, ensuring that your components are made to their exact specifications.

Material Expertise: We turn a wide variety of materials, from hard metals like titanium to engineering plastics, ensuring the right fit for your project.

Comprehensive Service: With our full range of ISO certified CNC machining capabilities, including milling, turning, finishing, and assembly, Summit CNC is your one-stop shop for all your machining needs.

Request a Fast CNC Quote today!

If you’re looking for a CNC machine shop that offers 5-axis turning capabilities with a focus on precision and efficiency, look no further than Summit CNC. Request your Fast CNC Quote today or Contact us to learn more about how we can support your next project with our industry-leading CNC turning services.