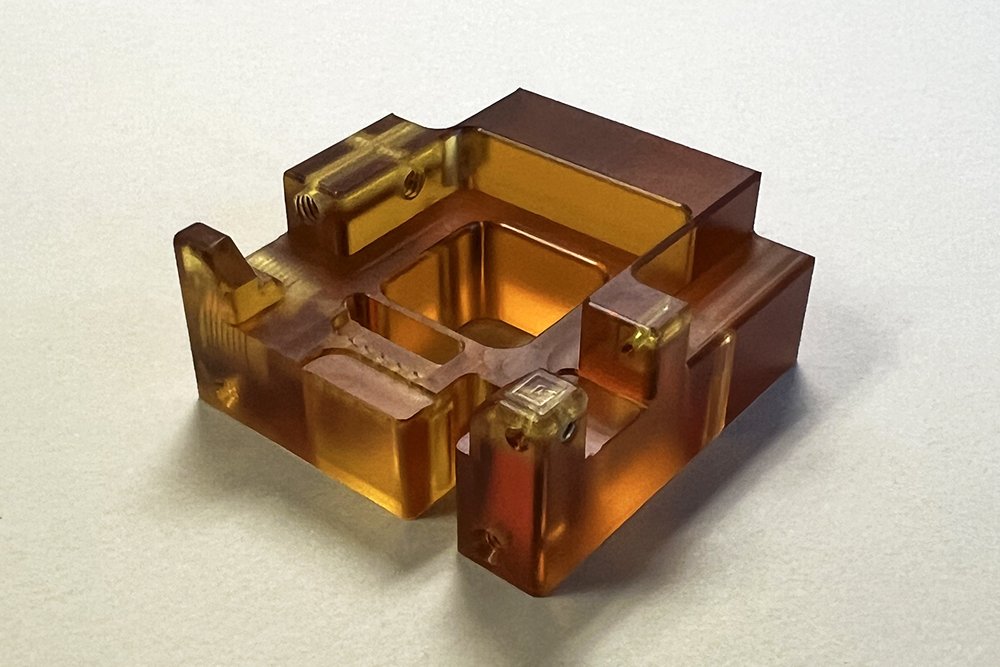

Prototype CNC Machining

Are you looking for a precision machine shop that can machine prototype part quantities of one or more? At Summit CNC, we are prepared to tackle even your most challenging prototype machining needs. Our ultimate goal is to provide a solution not only for your machined parts during the prototyping process, but to transition your prototype designs into our CNC production machining services, right here on the same machine shop floor.

There are specific advantages of working with the same precision machine shop for both your prototype and production machining needs. Through collaboration with you and your team, we develop a deep understanding of how to machine your part to specification during the prototype machining phase. Next, we can seamlessly transition a CNC prototype part to production machining and you can expect the same quality and attention to detail each step of the way.

Prototype Machining Capabilities

Our CNC prototype machining services consist of the following. We work closely with our customers to provide them with effective Design for Manufacturing (DfM) guidance.

High-Speed CNC Milling

Capacity: 41.3" (X) x 22.4” (Y) x 20.0” (Z)

CNC Turning with Live Tooling

Max Turn Diameter: 11.8”

Precision Tolerances (down to +/- 0.0002 in (+/- 0.005 mm)

Hardware Integration (dowel pins, helical inserts, etc.)

CMM Inspection

Finishing Services (anodization, passivation, plating, powder coating, etc.)

Assembly

From Prototype to Production

Summit CNC provides a one machine shop solution, with full capabilities and expertise to take your team from prototype to production. Below, are key factors that make us the best precision machine shop to partner with for both your prototyping and production CNC machining services:

Quick Quotes - We quickly respond to customer inquiries. In most cases, we will respond with a quote to you and your team within 4 business hours.

Collaboration - We can help you optimize your part designs (design for manufacturability or DfM) for CNC machinability, helping you reduce costs and lead times. We invite clients to schedule a tour of our machine shop and meet with us in person. Please contact us to schedule a tour or a video conference meeting. We also appreciate the opportunity to visit customers’ locations and meet your teams directly.

Prototype and Production Quantities - Whether you are in need of part quantities of 1, 100, or 1000, Summit CNC has the equipment and capabilities to machine your parts.

High Quality CNC Machining Services - As an AS9100D compliant precision machine shop, we have the processes and capabilities necessary to machine your parts to specific quality specifications.

Finishing Processes - We partner with trusted finishing shops that deliver high quality services for anodization, passivation, plating, powder coating, and many more.

Fast Lead Times - Lead times can vary depending on project complexity, line item and part quantities, and inspection requirements, but overall, our lead times are typically 1 - 4 weeks depending on finishing and material requirements.

Prototype Machining Materials

From plastics to hard and soft metals, Summit CNC has the experience and expertise to machine the material(s) you need for your prototype CNC parts. Below are some of the materials we machine. This is not a comprehensive list, so if you do not see the material you need, please contact us directly.

Aluminum (2024, 6061, 6063, 7050, 7075, MIC-6)

Alloy Steel (4130, 4140)

Brass

Carbon Steel (1018, 1045, A1008, A36, C1026)

Hard Metals and Soft Metals

Copper

Glidcop

Inconel

Monel

Nickel

Nitronic 50, 60

Stainless Steel (300 series, 400 series, 15-5, 17-4)

Titanium Grade 1, 2, 3, 4, 5, 7

Polycarbonate

Polycarbonate (Glass Filled)

Polytetrafluoroethylene (PTFE)

Semitron® ESD 410C PEI

Acrylic

Delrin

HDPE

PEEK

Plastics

TECAFORM

Ultem

What Customers are Saying About Us

“Great company! I needed a specific part for a project I was working on. It was machined quickly and arrived in great condition. Everyone was extremely friendly and helpful. Couldn't recommend this company more.”

Matthew Kinsky, Engineer

“On behalf of a business, I needed a special tool modified. The job was small but needed to be accurate and after calling over 8 other machine shops, Summit CNC were the only ones willing to do the job. 10/10 will use for future CNC machining work.”

Marco Zelaya

Summit CNC

ITAR Registered

3211 West Hampden Ave, Englewood, CO 80110

(303) 285-2211

service@summitcnc.com