Production CNC Machining

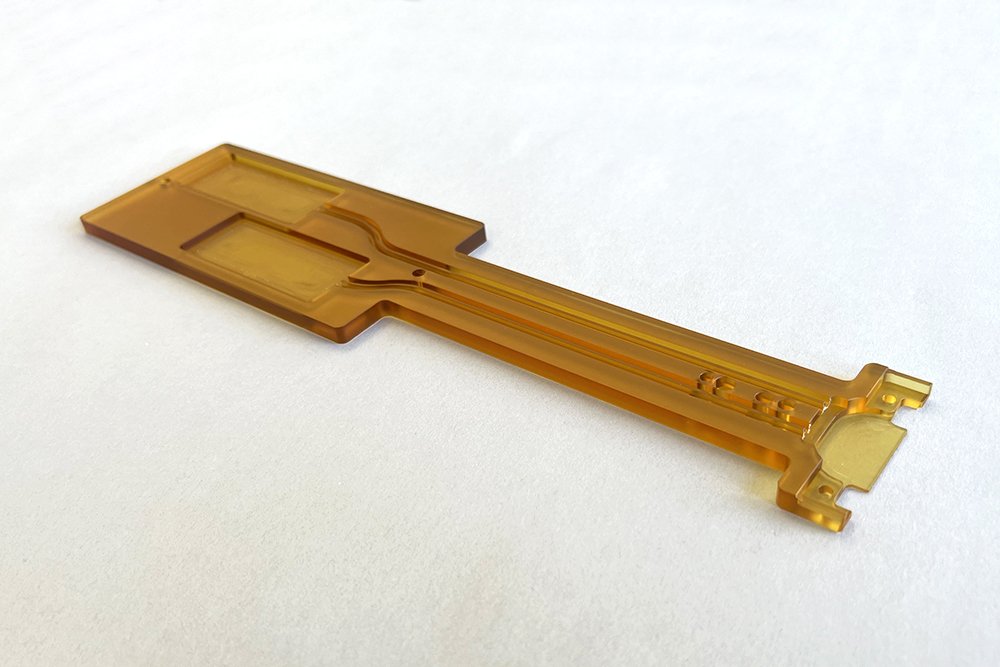

Are you in need of a reliable precision machine shop to manufacture your production parts? Whether you are seeking part volumes of 5, 100, or 1000, Summit CNC has the equipment, processes, and capabilities to machine your parts on-time to specifications. Using our heavy and rigid DN Solutions high speed milling and turning centers, we commonly machine production parts with demanding tolerances (down to .0002” or +/- 0.005 mm).

To ensure the best production experiences for our customers, we process all production orders through our rigorous quality management system so we can provide superior quality and on-time delivery.

Production Machining Capabilities

High-Speed CNC Milling

Capacity: 41.3" (X) x 22.4” (Y) x 20.0” (Z)

CNC Turning with Live Tooling

Max Turn Diameter: 11.8”

Precision Tolerances (down to +/- 0.0002 in (+/- 0.005 mm)

Hardware Integration (dowel pins, helical inserts, etc.)

CMM Inspection

Finishing Services (anodization, passivation, plating, powder coating, etc.)

Assembly

Unmatched Precision Machining and Repeatability

When it comes to precision and repeatability for your production CNC parts, rigidity is of utmost importance. For this reason, we only use heavy and rigid high speed machining centers. In addition, we outfit all of our milling and turning centers with state-of-the-art Schunk workholding systems. While many machine shops are unwilling to make the significant upfront investment these premium workholding systems require, the time they save and the quality they produce for our customers is worth it. No mattering who is operating the machine, we witness clamping repeatability of +/-0.0001”. This means that your parts are positioned and held in the vice the exact same way every time, even if the last time we machined them was several years ago.

Production Machining Materials

From plastics to hard and soft metals, Summit CNC has the experience and expertise to machine the material(s) you need for your production CNC parts. Below are some of the materials we machine. This is not a comprehensive list, so if you do not see the material you need, please contact us directly.

Hard Metals and Soft Metals

Aluminum (2024, 6061, 6063, 7050, 7075, MIC-6)

Alloy Steel (4130, 4140)

Brass

Carbon Steel (1018, 1045, A1008, A36, C1026)

Copper

Glidcop

Inconel

Monel

Nickel

Nitronic (50, 60)

Stainless Steel (300 series, 400 series, 15-5, 17-4)

Titanium

Acrylic

Delrin

HDPE

PEEK

Plastics

Polycarbonate

Polycarbonate (Glass Filled)

Polytetrafluoroethylene (PTFE)

Semitron® ESD 410C PEI

TECAFORM

Ultem

“I recently had the pleasure to hire the services of Summit CNC for 3D printing and CNC machining multiple components for some research projects and I must say that the service and craftsmanship I received were truly exceptional. Brian and Jason are true professionals in this business and provided very sound technical suggestions in order to get us the ideal end product and were very receptive of our many questions and queries.

They machined a sample for us completely unprompted and that shows their ethic and dedication to the customer. Their lead time was astonishingly short and kept me in the loop through the entirety of the process. Their online quoting system makes the transaction very easy to execute and eliminates any communication delays.

I would HIGHLY RECOMMEND using them for any additive or subtractive machining needs you have may across the US.”

Ojasvin Arora, Mechanical Engineer

What Customers are Saying About Us

Summit CNC

ITAR Registered

3211 West Hampden Ave, Englewood, CO 80110

(303) 285-2211

service@summitcnc.com