Project Feature: Machining a Complex Delrin® Prototype Manifold

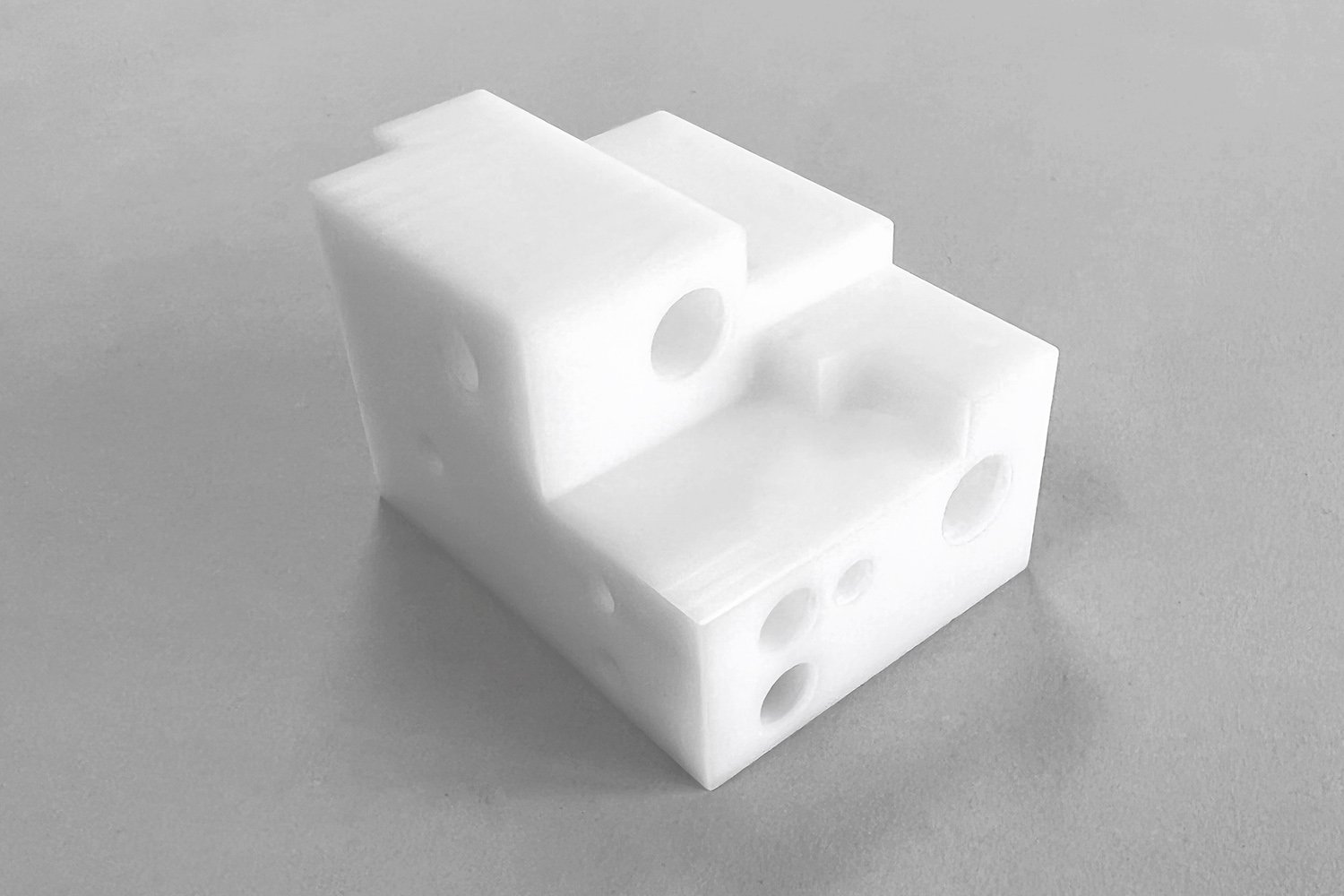

We are grateful for opportunities to make parts for unique applications, such as this Delrin manifold we recently machined for one of our customers.

This machined prototype was uniquely complex, making it challenging and fun to machine! We tackled this one the same way we always do: with skill and creativity.

Machining an Intricate Manifold

Our customer asked us to machine a manifold prototype designed for medical use in the field. This labyrinthine part required extensive non-standard tooling and multiple operations on one of our 3-axis CNC mills. The material we used was Delrin plastic, an acetal homopolymer ideal for prototype CNC machining services due to its durability, strength, and structural integrity.

As you know, manifolds transmit liquid, air, or gasses into connecting pipes, tubes, pumps, fittings, and more. This manifold required precise machining and a tight tolerance fit to interlock with the customer’s existing fluid channeling apparatus.

We strategized a multi-pronged approach that would enable us to meet our customer’s requirements and deliver top-quality prototype machining with a quick turnaround.

Here’s what made this part challenging to machine:

Number of tools

Machining this part required a total of 48 toolpaths throughout six operations using 17 different tools. With the average part requiring only 7-8 tools, you can see why this was an unusually involved process.

Deep channels

The deep channels in the design called for multiple customized drills measuring up to 12x diameter length. With so many channels intersecting throughout the block, we had to carefully program the correct depths, causing them to appropriately intersect with one another.

Multiple tap types

To ensure a precise fit, we tapped the machined prototype’s numerous channels with various thread types, including coarse-pitch UNC threads, fine-pitch UNF threads, and parallel NPS threads.

While many online marketplaces advertise multiple tap types, few have the breadth of tap tooling to do the job effectively. But here at our precision machine shop, we keep even some seldom used tooling in-house and will happily order any tooling we don’t already have.

We tapped UNC threads in areas that would hold removable hardware, UNF threads in sections with more permanent affixation, and NPS threads to ensure securely sealed joints with connected pipes.

Undercuts

This manifold’s design included several precision undercuts—features that not every precision machine shop will perform. Because Summit CNC frequently performs undercutting, we were equipped to create precise 0.29” deep key cuts with tiny diameters in just a few days.

Delivering the Finished Part

Upon completion, we went the extra mile (literally) and delivered the machined manifold directly into our customer’s hands. He was impressed with the part’s quality and proceeded to share with us about its unique application and how he plans to test it for field use.

It’s important to share that this project did not come without its unavoidable setbacks. When the lead time for some of the custom tooling we needed got delayed and caused us to adjust the customer’s estimated lead time for the machined prototype, we kept him informed and updated throughout every step of the process. We discovered once again, how our emphasis on customer service and communication is vital for building trust.

The customer has since chosen Summit CNC for additional prototype machining services, and we are very grateful for these opportunities.

Do you need prototype machining services? We’re here to help! Request a quote to get started.