CNC Machining Blog

Considerations for Precision Machining Hard Metals

Hard metals are the only choice for certain medical, aerospace, defense, energy, and other CNC machining applications. But if you need machined parts made from a material like 400 stainless steel, Inconel, or titanium, it is important to find a precision machine shop that is truly capable of machining these materials to your desired specifications.

Advanced CMM Inspection Capabilities at Summit CNC

When you order parts with critical precision tolerances or outlined GD&T specifications, you need to know that you’re getting exactly what you’ve paid for.

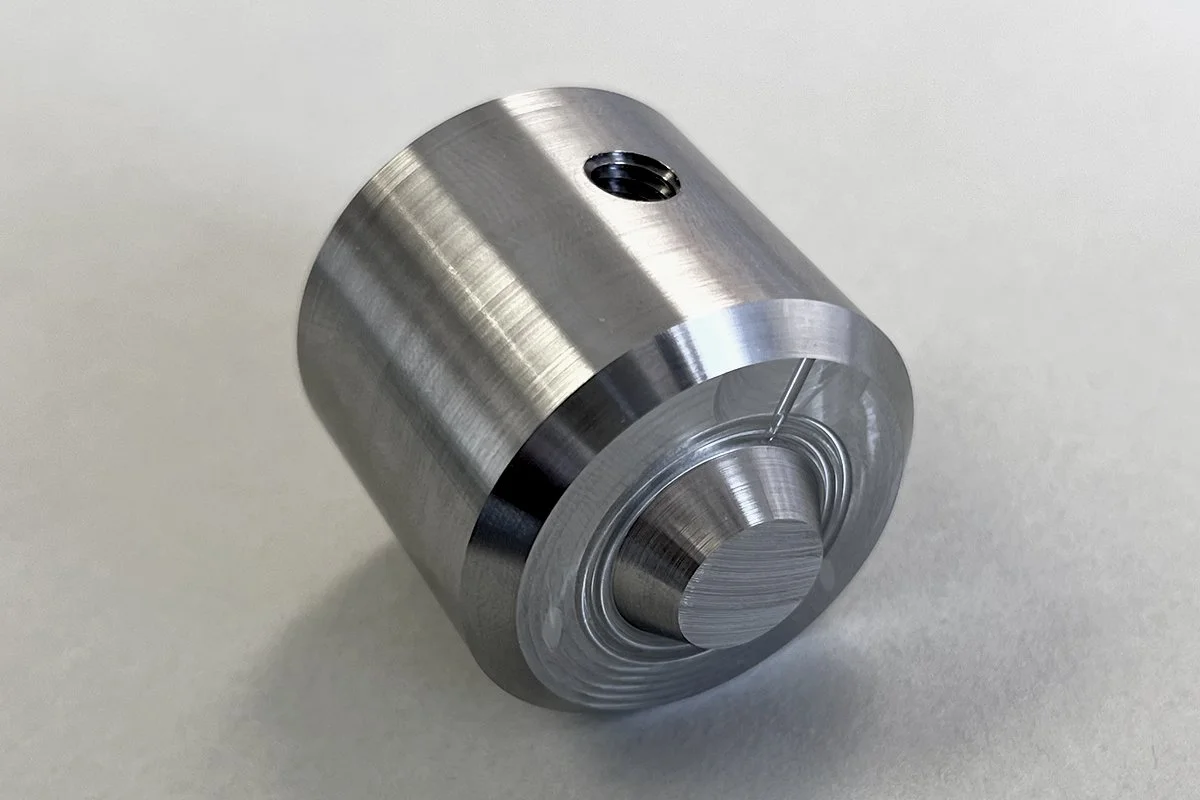

NEW! Precision Workholding for Tight Tolerance Parts

Tired of inconsistencies across low-volume part runs? So were we! That’s why we’ve equipped Summit CNC to make low-quantity, high-precision parts with unparalleled quality. Through extensive research, we were able to eliminate key obstacles to low-volume manufacturing success and establish processes that ensure superior quality on every size run.

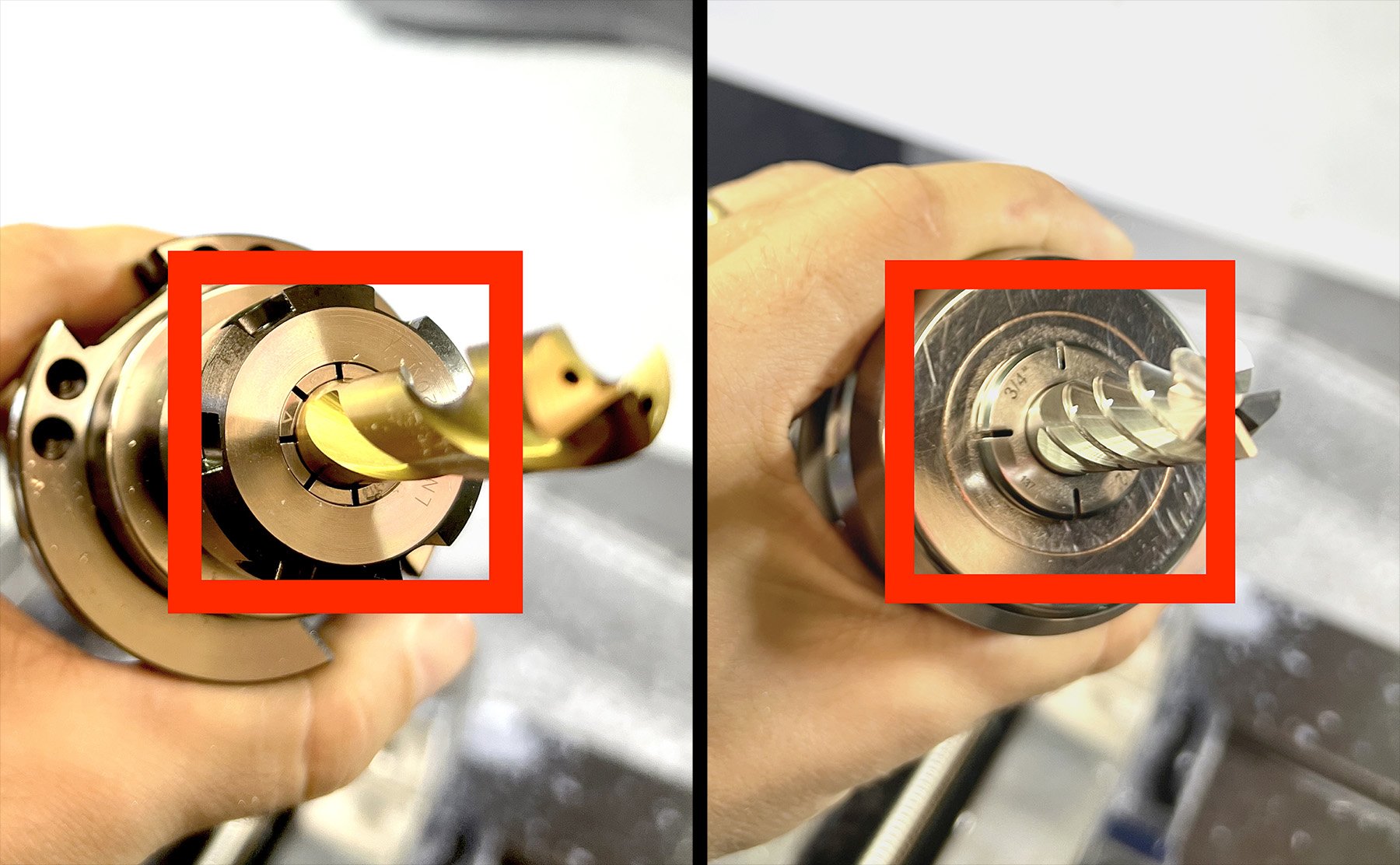

Machined Undercuts: Why We’re Your Go-To Precision Machine Shop

“Do you machine undercuts?” We’ve heard this question quite a bit lately, mostly from engineers looking for a precision machine shop that can perform their designs’ critical undercuts.

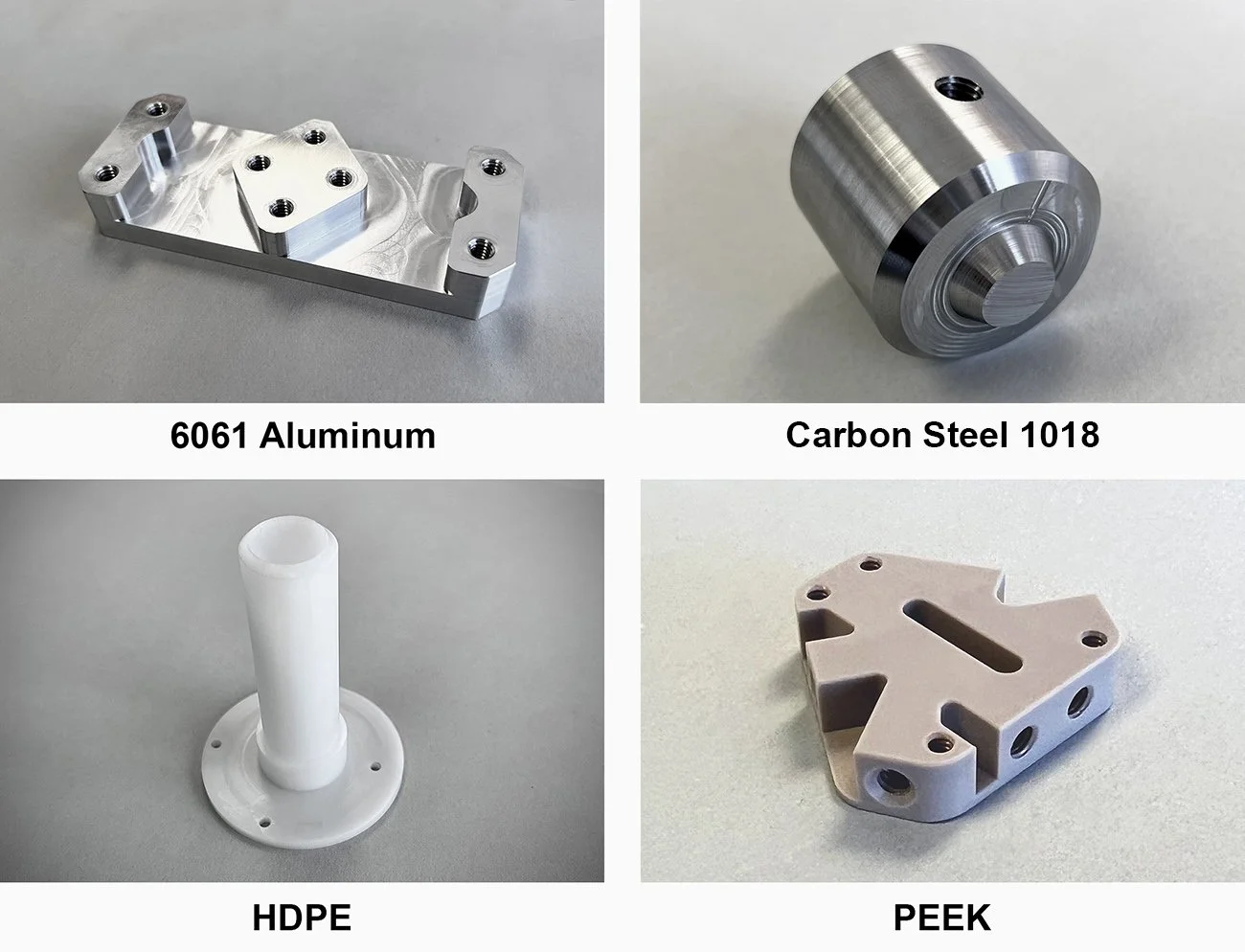

Why Choose a Material Agnostic Precision Machine Shop

When it comes to manufacturing, we’re what you might call “material agnostic,” meaning we accept almost any plastic, composite, soft metal, or hard metal for precision machining.

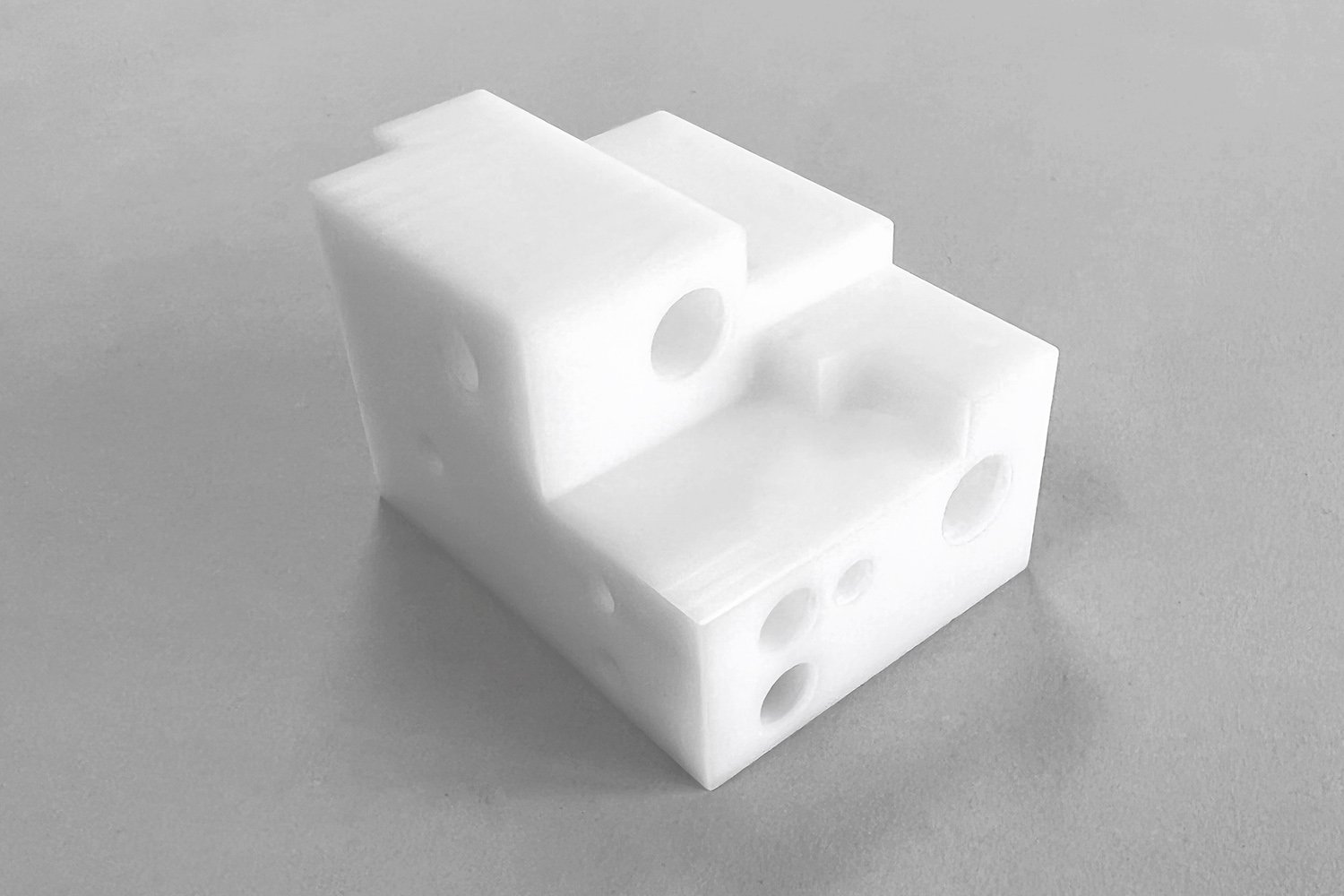

Project Feature: Machining a Complex Delrin® Prototype Manifold

We are grateful for opportunities to make parts for unique applications, such as this Delrin manifold we recently machined for one of our customers. This machined prototype was uniquely complex, making it challenging and fun to machine! We tackled this one the same way we always do: with skill and creativity!

How to Source Tight Tolerance Machined Parts in the US

Have you had lackluster experiences ordering precision CNC machined prototype or low-volume production parts from online manufacturing marketplaces or other machine shops? While standard tolerances of +/- 0.005” (0.127 mm) are achievable by many shops and even some online marketplaces, precision tolerances are oftentimes a whole different story.

When Precision Machine Shops Source Materials Domestically, You Win

Summit CNC is on a mission to buy locally—whenever possible, we source our manufacturing materials from US suppliers, defying a long-held belief that offshore sourcing is the best way to reduce costs. In fact, offshoring is no longer the logical solution it once was. While opportunities to buy cheap stock from overseas do still exist, continued offshoring has more downsides than benefits.

4 Ways Engineers Can Save Time and Money on Precision Machined Parts

At Summit CNC, we have immense respect for design engineers everywhere. Engineers are the source of all parts—without them, we wouldn’t be here doing what we love and bringing their parts to life on our shop floor.

How We Achieve +/- 0.001” or Better Tolerances at Our Prototype Machine Shop

Since opening the doors to Summit CNC, we’ve developed a reputation for superior prototype and low-volume production CNC machining services. There are many factors that set us apart from other prototype and low-volume production machine shops.

Made in the USA: The Importance of American Manufacturing

One of the reasons we founded Summit CNC is because we're passionate about American manufacturing. We belong to a third-generation manufacturing family from Salina, Kansas and we've seen how this industry has changed over the years, as many jobs have unfortunately been outsourced overseas.

Rapid Prototyping Services for Research & Development

There’s no shortage of production shops providing services to the aerospace, electronics, medical, and other industries here in Colorado. There are also plenty of on-demand industrial parts marketplaces promising the world to engineers.

Design for Manufacturing (DfM) Best Practices for CNC Machined Parts

When you come to Summit CNC for precision machining services, we want you to get the best quality parts quickly and cost-effectively. We’re committed to doing everything we can on our end to achieve this goal.

Do You Know Who’s Manufacturing Your Parts?

There’s no shortage of on-demand industrial parts marketplaces that are promising the world to manufacturing customers who order parts. While these solutions seem convenient at first glance, we’ve worked with many customers who end up disappointed by their sub-par part quality and lack of customer service

Our Story: Get to Know Summit CNC

As we prepare to publish our inaugural blog posts, we want to take this opportunity to share a bit more about ourselves. We’re Summit CNC, a precision CNC machine shop, serving primarily the aerospace, medical, and defense industries, among others.

Summit CNC

ISO 13485:2016 Certified

ITAR Compliant

3211 West Hampden Ave, Englewood, CO 80110

(303) 285-2211

service@summitcnc.com